Quality

QUALITY MANAGEMENT SYSTEMS

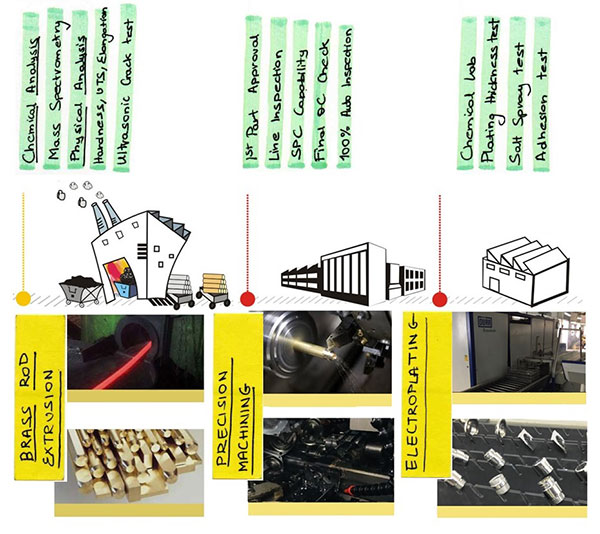

We follow the ISO 9001 and IATF 16949 quality management systems and are a certified supplier to the Industrial Engineering and Automotive companies. We have routine internal and customer audits to verify our systems. The products we manufacture are traceable from the bar to the box; and their quality is checked at multiple stages during the production process.

ADVANCED QUALITY PLANNING

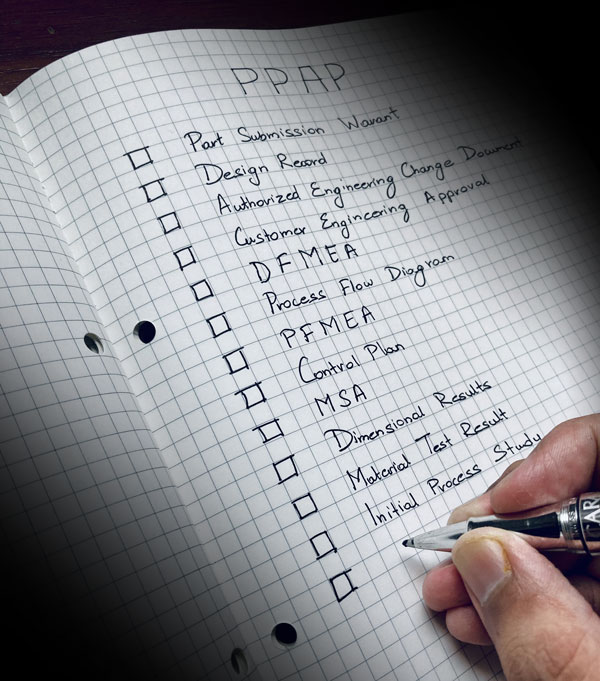

We invest in training our engineers and associates in quality systems and quality tools to ensure a quality mindset. During development we use tools such as APQP (Advanced Product Quality Planning), PPAP (Product Part Approval Process), PFMEA (Process Failure Mode Effects Analysis), SPC (Statistical Process Control, MSA (Measurement System Analysis), R&R (Repeatability and Reproducibility) among others.

QUALITY CONTROL EQUIPMENT

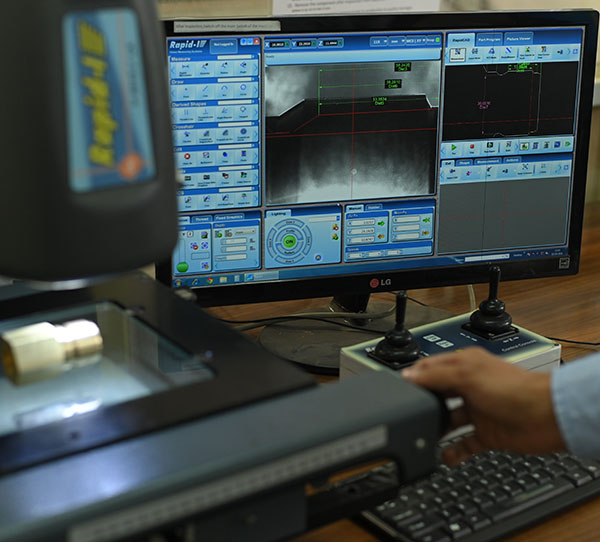

We invest in state of the art quality control equipment allowing us to deliver technically perfect parts. The material we use is tested for its chemical composition using mass spectrometry, physical properties, and upon request ultrasonic crack testing. The parts we produce are tested on using custom gauges, optical measurement, contact measurement. We also have equipment for automated visual sorting. We have equipment to check the thickness of the plating on our products and to salt spray test the life of the coating.

Environment

We take our responsibility towards the environment.