End to End Manufacturing

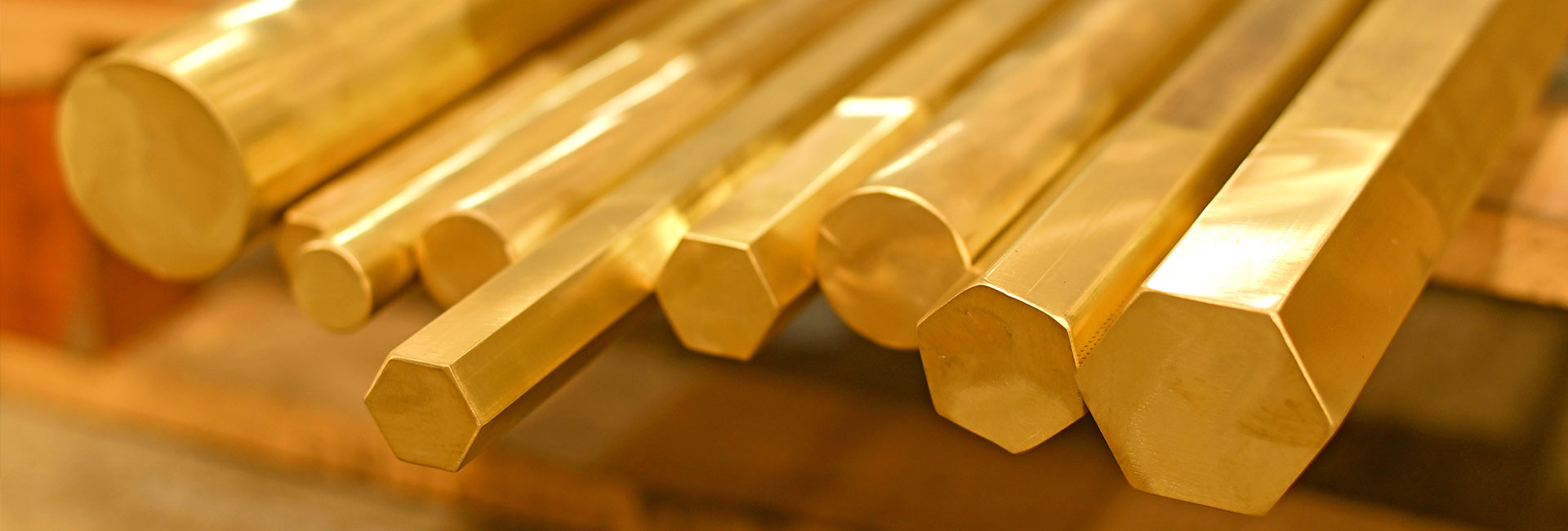

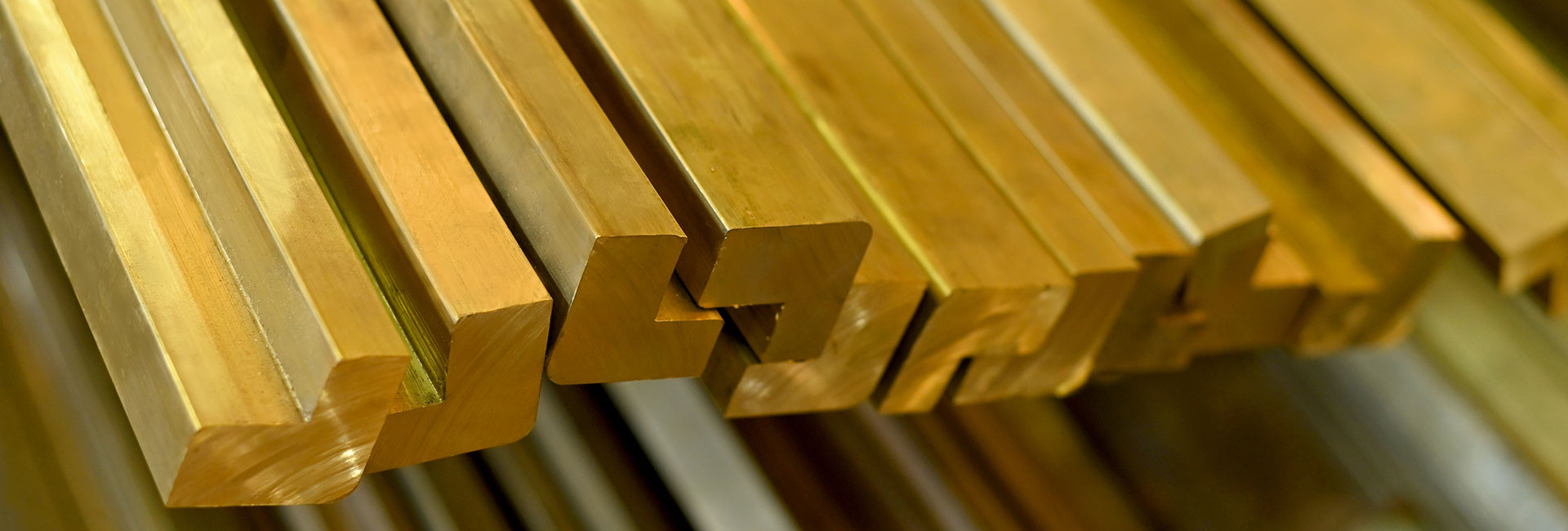

BRASS ROD MANUFACTURING

Our in-house extrusion plant is ISO 90001:2015 certified and allows us to make various grades of Brass and Copper alloys. We are able to process lower MOQs and custom shapes. What we offer is a competitive purchase price with shorter lead times.

HEAT TREATMENT

Our inhouse heat treatment facilities allow for the annealing and hardening of brass machined parts. We also have ISO certified vendors for heat treating all other materials including processes such as quenching, normalizing and carburising.

PARTS CLEANING

All parts shipped are cleaned and degreased before shipping. We use a hydrocarbon solvent closed loop cleaning system, with vacuum suction which ensures zero atmospheric emissions. We also do bright dip and passivation when required.

Electroplating

We started an inhouse surface treatment facility to make high gloss (polished and buffed) chrome plated parts. We are able to meet the strictest aesthetic requirements. Our plant specializes in nickel, zinc and chrome electroplating. This allows us to provide suggestions and resolve technical problems quickly and reliably. We also outsource some surface treatments such as hard chrome plating and anodizing.

Automated Inspection

We have SPC capable machines inspecting the accuracy of the product by checking the dimensions and appearance. These machines use an image-based pass/fail evaluation system; preventing defective products from reaching our customers.

Laser Marking

Whether your requirement is branding or traceability, our machined parts can be laser or punch marked with a logo or date of manufacturing.

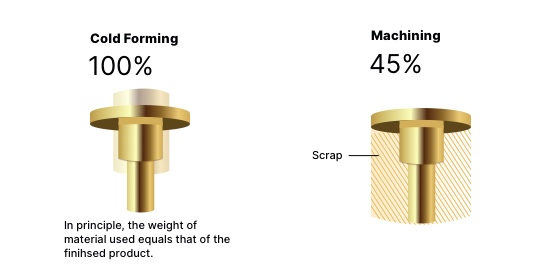

COLD FORMING

JAKAP provides solutions for your metal parts, our cold forming machines use a deep drawing process that allows for more efficient material utilization. To know more about if your requirements can be met through cold or hot forming contact us